TOYO YOZAI Co., Ltd.

23-14, Minami-cho, Itabashi-ku Tokyo, Japan 173-0027

TEL: +81-3-3974-1731

FAX: +81-3-3974-1777

Osaka Shoji Co. Ltd.

Contact information for purchase and inquiries

www.osk-21.co.jp

osk@osk-21.co.jp

Deoxidation chemical compound

for Copper tube brazing

It’s TOYO’s New Magic

TOYO CLEAN COPPER!!

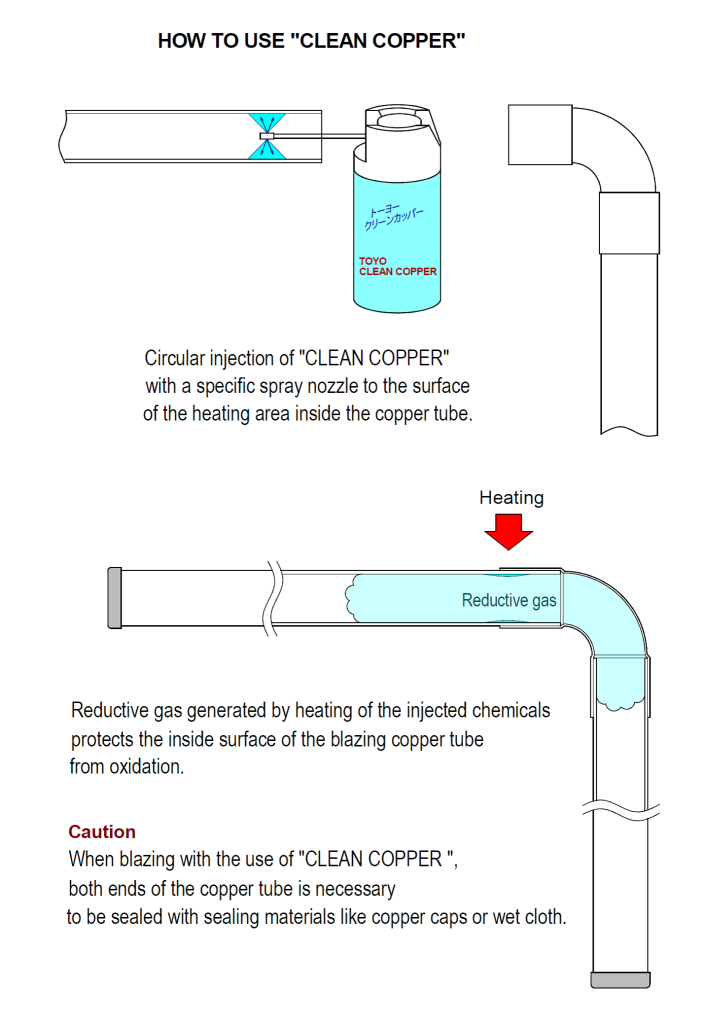

Spraying this CLEAN COPPER

into copper tubes prevents them

from oxidation and keeps clean surface.

US Patent

No.6053396

Japanese Patent

No.3231009

Download Instruction manual

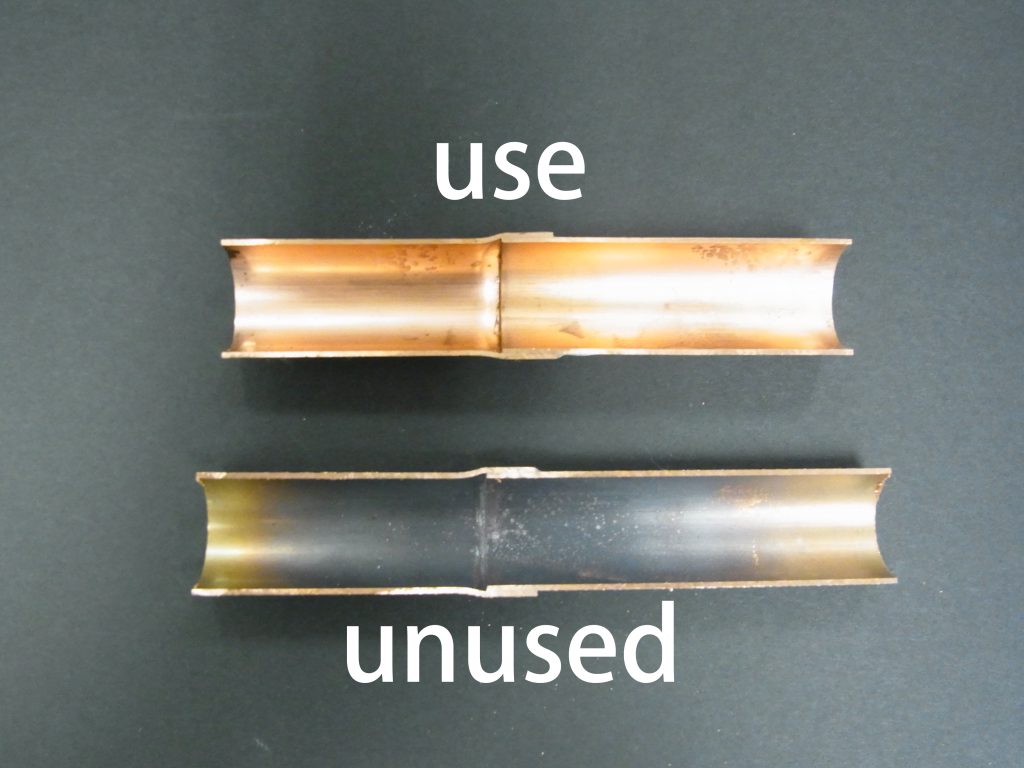

Top shows oxidized scales formed inside the copper tube by brazing without using TOYO CLEAN COPPER. The scales give serious damage to the system.

Bottom shows the inside of the copper tube after brazing with the use of TOYO CLEAN COPPER. The copper surface keeps clean enough for longer life of the system.

Superior quality deoxidation spray for copper tube brazing

To prevent oxidation of the inside surface of copper tubes at the brazing time, CLEAN COPPER has following advantages over usually used N2 sealing method that fills whole tubing system with nitrogen-gas.

- A can of TOYO CLEAN COPPER is very light (200 g) and easily handled. On the other hand, the nitrogen gas source is a very heavy cylinder to handle and takes time to replace air in piping with nitrogen gas.

- Long life of system due to long lasting its effect

- Shortening of the work time and lower cost than nitrogen sealing method.

Example of application

- Refrigerant piping system for large size business buildings such as office buildings, shopping centers, supermarkets, etc. (both at the time of new construction and renovation of the system)

- Air-conditioning/Refrigerating system in ocean vessels

Recommended method of application

- Clean well inside of the joint to be brazed

- Shake well TOYO CLEAN COPPER can before use

- Seal one end of the copper tube, and then, spray TOYO CLEAN COPPER into the copper tube from another end.

- Seal both ends of the tube before brazing

- After brazing, leave the brazed tube as it stands for cooling down